Company

50 YEARS GAINING EXPERIENCE ON DESIGNING AND MANUFACTURING HAND TOOLS.

Antonio Sampedro founded Forza, a family owned business pioneer in the Spanish special tools manufacturing market. Mr. Sampedro was not only an entrepreneur but most importantly, he had a passion for metal working combined with a continued thrist for new products and tools and manufacturing process development.

Throughout this time, Forza has been faithful to the values that inspired him.

THE TOP QUALITY OF THE TOOLS IT IS OUR BEST GUARANTEE

50 years banking on quality in design, manufacturing and service. The prestige of our products lies in a strategic focus on innovation, tailor made tools and over the top raw material.

Forza is a leading manufacturer of Special tools relied on a team of committed young professional bringing a large breath of experience.

We have a deep sense of quality that it is reflected into a full warranty on all the parts we produce.

“UNLIMITED” MANUFACTURING CAPABILITY OF CUSTOMIZED PRODUCTS.

The enthusiasm and hard work of our I+D department together with Engineering are expressed on our complete catalogue that includes an extensive range of demanded hand tools (specialized on pulling solutions) but also knockout metal punches, Automotive tools and machine vices as well.

Our customers and potential customer’s needs are our high priority and we are completely opened for the designing and manufacturing of new customized products.

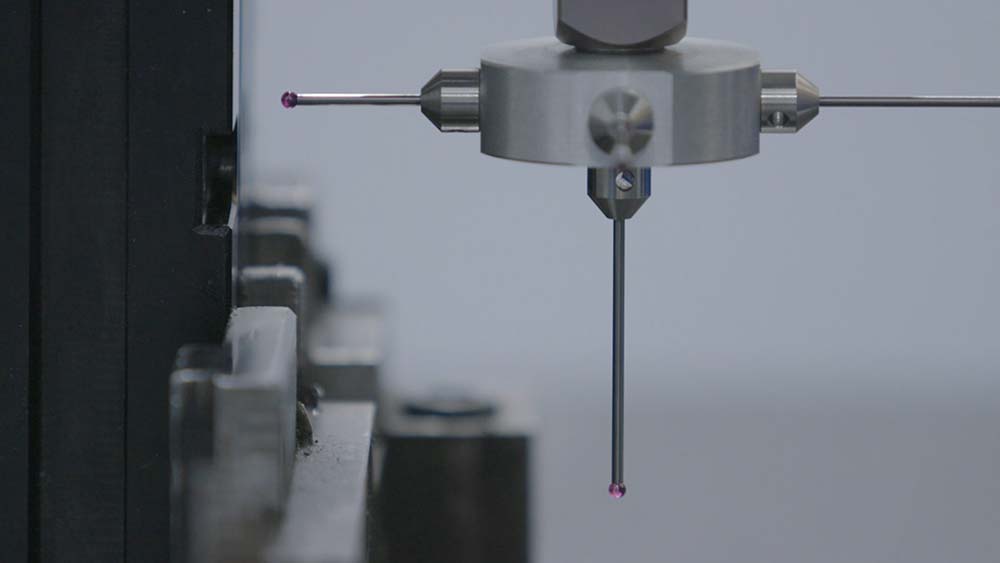

TECHNOLOGICALLY PIONEERS IN MANUFACTURING SYSTEMS.

Innovation is part of our DNA since our Forza’s origins. We are continuously being pioneers in Spain in the implementation of new production systems, developing and patenting innumerable products.

We therefore support and contribute to the change of Industry 4.0 by applying the Lean Manufacturing philosophy.

ENVIROMENTAL SUSTAINABILITY COMPROMISE.

At FORZA we proudly follow stringent environmental, energy saving, waste selection and raw material recycling principals.

Thanks to our 3 plants, we generate more than 100KW/h annually through our solar panels installation. This figure amounts to approximately 1607 trees/year for carbon dioxide consumption.

FORZA Herramientas S.L. has improved the energy efficiency of its productive process by investing in a GROB G550 5-axis single-spindle universal machining centre with a 3D CNC contouring control which provides a reduction in electricity consumption. All this within the framework of project 356-AEE/2019, which has been co-financed by the European Regional Development Fund (ERDF), managed by EVE-IDEA under the National Energy Efficiency Fund.